There are many important things to consider when choosing the perfect concrete diamond core bit. In modern construction, these bits are a critical component and tools sui used should offer precision, efficiency as well durability. Top of the list is concrete diamond core bits which are highly popular because they can cut through one of toughest materials in construction with absolute ease. Drill bits featuring diamond tips are the best that drilling technology has to offer, as they make it easy for you to drill holes in a precise and neat manner along with being fast enough not be time consuming. As the construction industry heads further towards digital transformation, it is becoming even more important to know how to properly choose and use (and maintain!) these amazing gadgets.

You are here: Home / Concrete Drilling Tools Help / The Ultimate Guide to Choosing the Right Diamond Core Bit for Your Job

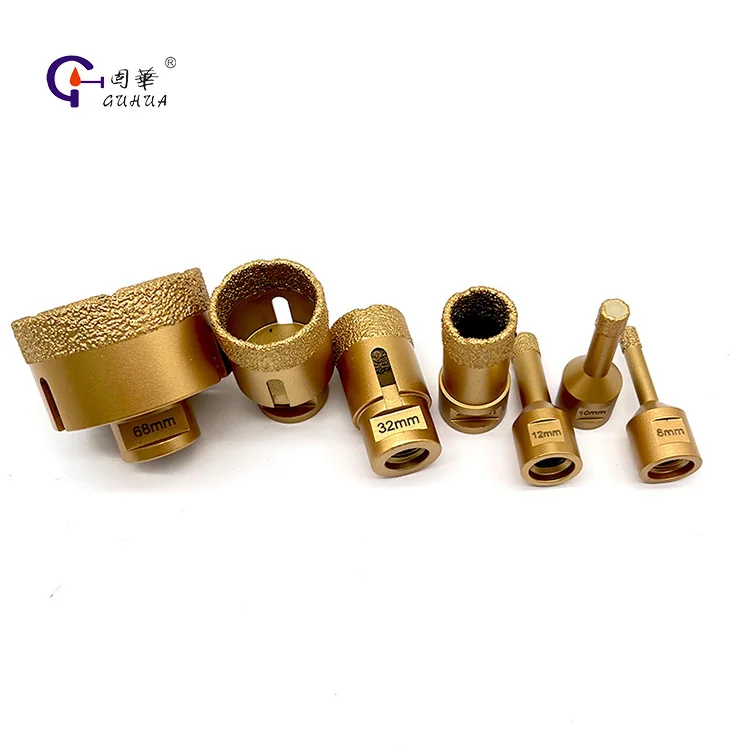

The diamond core bit is the most important tool in any concrete drilling project. There are several important factors you need to consider when making this kind of decision. For one you need to know what size hole and what type of concrete (reinforced or not) is being drilled, as well as the depth. The bit's bond hardness also must be considered - hard bonds are ideal for abrasive materials, while soft bonds work well in less abrasive conditions. The segment height and barrel length of the core bit are important factors that influence how long the tool will last, and drilling deep holes with ease.

Many professionals in the construction industry use diamond core bits for good reasons. Compared to the traditional carbide tip bits, they are a faster and more efficient method which dramatically cuts downtime as well as labor costs. Diamond bits also produce cleaner and more accurate holes, which is very important in applications such as installing pipe or laying cable or anchorage where precision plays a big role. Their resistance to heat and wear, a fact made particularly possible by how incredibly hard diamonds are, ensures these blades perform at their very best even when placed under heavy load which makes them a good investment for any contractor.

The prompt utilization of high-quality diamond core bits has taken construction projects to the next level. This leaves the core bits capable of drilling with little damage to surrounding structures ensuring that concrete, once drilled through, retains at least 90% ( ANSI Standards ) of it's original integrity after being successfully penetrated. Additionally, they allow for a variety of drilling patterns and depths never before experienced or possible in the open market; by increasing design possibilities these pieces are advancing project timelines. The ability to drill through reinforced concrete while leaving reinforcement bar intact is a game changer for safety and adherence in regions where strict construction standards are imposed.

Mastering concrete drilling is more than just picking the right core bit; you also need to master your technique and be prepared. Proper marking of the central point, and proper lubrication (usually some kind od water), are very important before drilling if you want to keep your machine intact. Proper knowledge of the RPM settings according to different sizes of bits and materials will prevent hotting up if you are a buying erp drill machines. Apply consistent, moderate pressure while drilling and remove dirt from the opening at regular intervals to enable smooth operation on overall optimal hole performance with prolonged bit longevity.

Extending the life of your concrete diamond core bits leads to financial savings and increased efficiency. The full maintenance process - particularly regular cleaning to eliminate concrete waste after each service - is essential. The first is to store bits in a moisture free and temperature controlled atmosphere as this preserves the integrity of such fluid sealer for longer periods. Having a monitoring system in place for the bit along with timely replacement of worn segments can prevent costly damage and loss of efficiency. Finally, if the bits can be rotated when in use then this will also help with even wear and longer life. Contractors who implement these practices can get the most out of their diamond core bits, making a substantial purchase into an enduring and lucrative one.

Overall, concrete diamond core bits represent essential components in the toolkit of contemporary construction professionals since they provide a trade-off between accuracy and strength for which classical alternatives just cannot compete. Proper material, processing and maintenance of these bits are some important things that should be done according to the tip-recycling techniques. However, the payoff is huge: smoother operations and better outcomes (with a bigger paycheck at the end of every project these are used in). As technology develops, so will these little bits of historic metals that have come to form the future face of construction drilling.

have over 20 years of international trading experience, working clients from more than 60 countries, now have local warehouses as well as subsidiaries located in the UK, India, Kenya. We can offer one-stop solutions to concrete diamond core bitworldwide, ranging starting from R D and production, to logistics after-sales services.

extensive production concrete diamond core bithas led us create rigorous Q C standards. products are strictly tested prior delivery, and include random inspection each process as well as quality inspections every component of key procedures. We've obtained SGS testing certification international ISO 9001:2015 quality management system certification and all Guhua products are MPA and CE safe.

With over 30,000 m2 factory space, advanced equipment, efficient production lines, we able to concrete diamond core bitquick responses orders offer high-quality items with high cost-performance to our global clients through efficient processes for production and stringent Q C guidelines.

Guhua has highly skilled R D team concrete diamond core bitof top engineers specialists who have been a part of the field more than 20 years. We've obtained more than 40 invention patents and a market leading innovator in the design, development, manufacturing brazed diamond tools that allow precision-built drilling, cutting, grinding tools to process various material types, including brittle and hard materials and sophisticated high-precision tools.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy