Expound the Key Aspects of Dry Diamond Core Bits

Dry diamond core bits are a certain type of tool you can use to help make your drilling tasks even simpler. While traditional drilling equipment might not be efficient, using dry diamond core bits has many benefits to ensure smooth accomplishment of your projects. We will focus on the different advantages, invention, safety measures safety application of dry diamond core bits in this article.

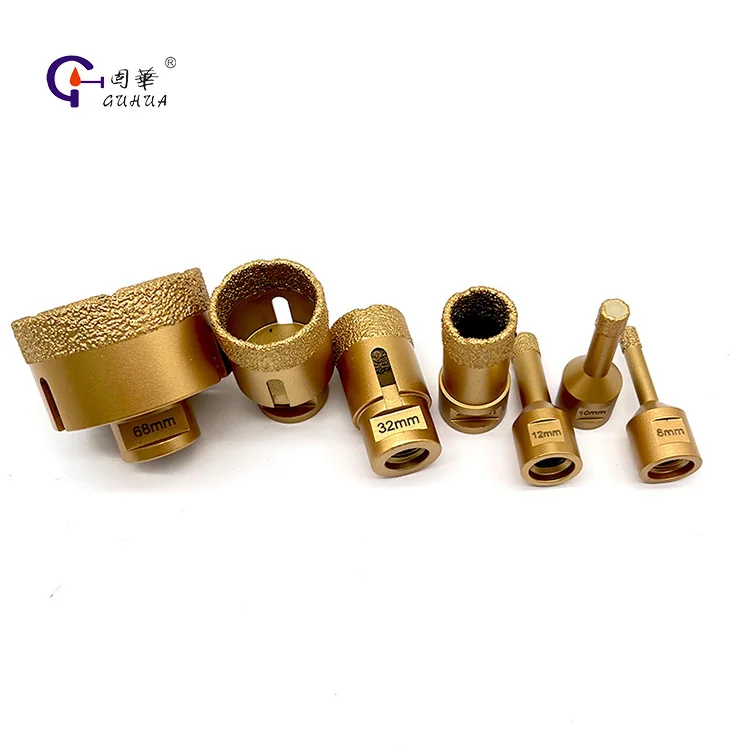

Advantages

Dry diamond core bits are a game-changer and have transformed the drilling world for good. These bits drill more quickly, last longer and produce less dust than traditional dry core bits. Using dry diamond core bits will help you avoid ruining the bit and creating a bunch of dust on your work site when drilling through difficult material such as concrete or brick. Further, these bits turn out to be economical in the long run as they do not need any water or other cooling fluids for their operation.

This in particular, the dry diamond core bits are a revolutionary product development for world of drilling. Combining the toughness of diamonds with durability, these bits are a huge step up from other drilling options. Laser-Welded Diamond Segments - These are attached to the drill bit for added strength and heat resistance. Dry diamond core bits are ideal for outdoor applications or locations where water use is restricted since the drilling process requires no water.

When drilling, safety is one of the most important aspects. Dry diamond core bits also create a safer environment to work in because dust and debris production nearly comes to whole stop comparing other types of drilling methods. What is more, due to the use of no water in procedure negating the risk of electric shock and slip-and-fall accidents it also makes for safer drilling operation.

Dry diamond core bits are among the most versatile tools that can be used during a wide variety of projects from plumbing and electrical installs, HVAC jobs to demolition & renovation work. Router Bits - These bits are made to drill thick diameter holes in tough substances like concrete, brick and stone which we need for all kinds of projects.

Proper Techniques for Use

The more modern dry diamond core bit is easier to use, but there are some tips and tricks you can follow to get even better results. First, choose the right bit size for your task and then secure it to your drill start drilling on a low setting. Apply gentle Pressure and continue increasing the speed so that the Diamond segments can do their work better. Once you have dug to the appropriate depth, remove the bit and clean away any debris for a nice final surface.

Service Considerations

The good news is that you need to get a dry diamond core bit there are plenty of places where excellent customer service and support can assist. A good supplier will help you choose the proper bit to suit your needs and even give instructions on how it is used. Also, seek out vendors that support their items with at least a warranty as well or guarantee which serves to protect the expenses benefit you are having.

Quality Factors

You Get What You Pay For Not all dry diamond core bits are created equal so be sure the quality of bit is job one when selecting a bit. Choose bits from credible high-quality suppliers who really put them through the ringer to prove they are strong and can stand up to tough conditions. When you go for the dry diamond core bit, your drilling will work topped; thus it can boost your drill operation.

Because of this, dry diamond core bits can be used in a variety of applications such as drilling holes for HVAC systems, electrical conduits and plumbing fixtures to anchor and dowel holes. Razor sharp, these versatile bits are capable of consistently and accurately completing a variety bonding operations that makes them an essential tool in any contractor's belt.

Dry diamond core bits are a testament to innovation and precision, which comes with numerous benefits compared to traditional drilling techniques. Consider quality and safety when looking to buy a dry diamond core bit for your next project so you can get better results. Ensuring durability, effectiveness and affordability on-site, dry diamond core bits provide a great asset for many different drilling projects.

With over 30,000 m2 factory space, advanced equipment, efficient production lines, we able to dry diamond core bitquick responses orders offer high-quality items with high cost-performance to our global clients through efficient processes for production and stringent Q C guidelines.

have over 20 years of international trading experience clients from over 60 countries. now have subsidiaries local warehouses located in the UK, India, and Kenya. are able to provide a single-stop solution to customers worldwide, ranging from R D and dry diamond core bit, to logistics and after-sales support.

Guhua has a skilled R D team consisting top engineers and experts who have deeply cultivated industry for over 20 years. hold more than 40 dry diamond core bit, and we the top company for developing, designing and fabricating brazed tools. lets us create deeply customized tools that used to treat a variety of materials including brittle ones also complex high-precision tools.

developed strict Q C standards based extensive production experience. Before shipment products, they are dry diamond core bitexamined, including random tests each process and quality inspections for each key procedure. We've obtained SGS testing certification international ISO 9001:2015 quality management system certification, and all Guhua products are MPA and CE approved for safety.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy