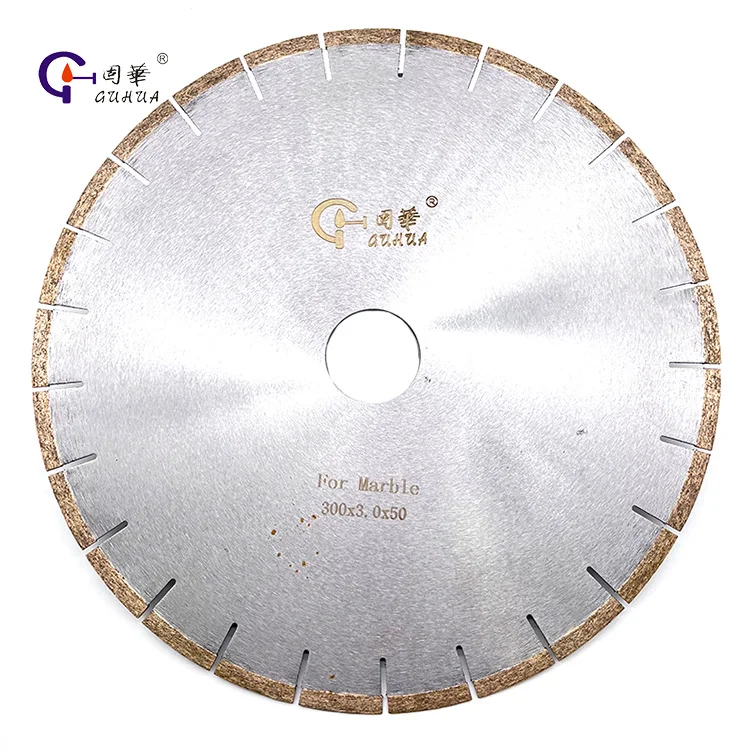

An Innovation From the Granite Cutting Blade for a Circular Saw

And if it's you, to be that one who has used probably everything in terms of circular saws - then possibly you would have a half-decent blade collection and diversification. Granite cutting blade is one of the crucial and most common used to buy blades. Its anti-kickback makes it best for quick, easy cutting in hard materials such as granite, marble or stone. Due to all these benefits, however, granite cutting blade is gaining more and worldwide significance in last few years. The advantages of using a granite blade, another focus:How do you ensure that it is safe in operation and where does one get many blades manufactured along with the latest technology to further assist your cutting edge.

Ease of use: Granite cutting blade has a special design that make it easy to work with hard materials such as tile and marble. These blades are made from the best, most durable material so they can handle whatever this gear requires. Granite cutting blades make your polygon cut fast and easy, not just as other blade works where it takes time for you to have a taste of an already heavy work done during regular diamond cuts without any application effort.

Innovations in Granite Cutting Blades :

The market of granite cutting blades industry has gone through some major technological advancements, which have reshaped the landscape. Currently, these blades are applied to more elaborate applications depending on the design and size. Robust grind cores heat-treated for laser finishesDurable new Grit Core diamond types Utilizing technological advances for true fits and design tolerances, as a result smooth tuned blades that run quietly while producing a consistent airflow.

Always remember that proper use of a granite cutting blade will ensure your safety, above all. Before changing the blade of your saw, always ensure you have switched off and disconnected it. In an attempt not to have any form of accident the blade should this be safely locked into Getting in all these protective tools when you feel like (goggles or sunglasses, ear protectors and gloves) which is a mandatory activity for cutting rock granite as well. Follow the safety standards provided by your manufacturer, and always use an appropriate blade for what is needed.

How to Utilize a Granite Cutting blade

Cutting granite with a digital saw is simple. Be sure the blade is designed to work with your saw, compatible with mfg. Insert the blade into the saw arm spindle carefully. Spindle nut to be finger-tightened (indicated the blade mounting position of teeth) fullyinandlockblade in allway -BLADE 1(cpibmacg)- Take it slow and turn the saw on until you have confirmed that the off-cut side of your granite worktops are positioned accurately.

The Importance of Regular Maintenance

You will want to clean off any debris, or if there is a buildup on the surface of the blade you should be setting up some routine cleaning for it. Inspect The Knife Daily Check the blade for any knicks or cracks and swap them out as needed. Preventable from harming the blade or decreasing its shelf-life; simply store it in a dry place and cover.

So if you are getting one for maximum performance, then ensure to get a high-quality granite cutting blade when the time comes. A quality blade will also endure through normal wear and last long-lasting for the money investment. Purchase it at stainless-steel, teeth and also branched reason laser blades together with warm addressed core cutter. Performance-wise they need to do quite well for every cut if you plan on keeping them around for a while. Since high-quality blades live for a long atime,pehaps the ideal solution is what you are looking.

Understanding the Versatility Of Granite Cutting Blades:

Granite stone cutting and polishing blades to cater anything from at home DiY projects through industrial applications, are of different types. This blade is able to cut granite countertops, marble stones and all other hard things this easy. For example, they are sometimes used in construction work such as building facades, monuments and floor tiles. That is why when it comes to cutting a hard material, you should definitely think for one of these granite blades.

Overall, there are numerous benefits associated with the use of granite cutting edges as compared to regular ones. Now, with the technology we have in construction and design these babies are our powerhouse tool today. Bosch 12V EC Brushless Impact DriverThis is the tool to go for if you are on hard granite, marbles and thatication. We trust this article will give beneficial information regarding the advantages, improvements in design and quality of Granite Cutting Blades. Simply put, be safe all the time when using a circular saw with granite cutting blade so you will end up in making your cutting process more saf and effective.

are able deliver products high quality granite cutting blade for circular sawcost performance thanks our effective production methods.

We've been business granite cutting blade for circular sawfor over 20 years. have clients across more than 60 countries. have local offices and subsidiary stores in the UK and also India and Kenya. are able to provide a single-stop solution our global customers ranging starting from R D and production logistics and after-sales service.

Guhua has highly skilled R D team granite cutting blade for circular sawof top engineers specialists who have been a part of the field more than 20 years. We've obtained more than 40 invention patents and a market leading innovator in the design, development, manufacturing brazed diamond tools that allow precision-built drilling, cutting, grinding tools to process various material types, including brittle and hard materials and sophisticated high-precision tools.

extensive production granite cutting blade for circular sawhas led us create rigorous Q C standards. products are strictly tested prior delivery, and include random inspection each process as well as quality inspections every component of key procedures. We've obtained SGS testing certification international ISO 9001:2015 quality management system certification and all Guhua products are MPA and CE safe.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy