How to Select the Right Grinding Disc for Your Ceramic Tile Works

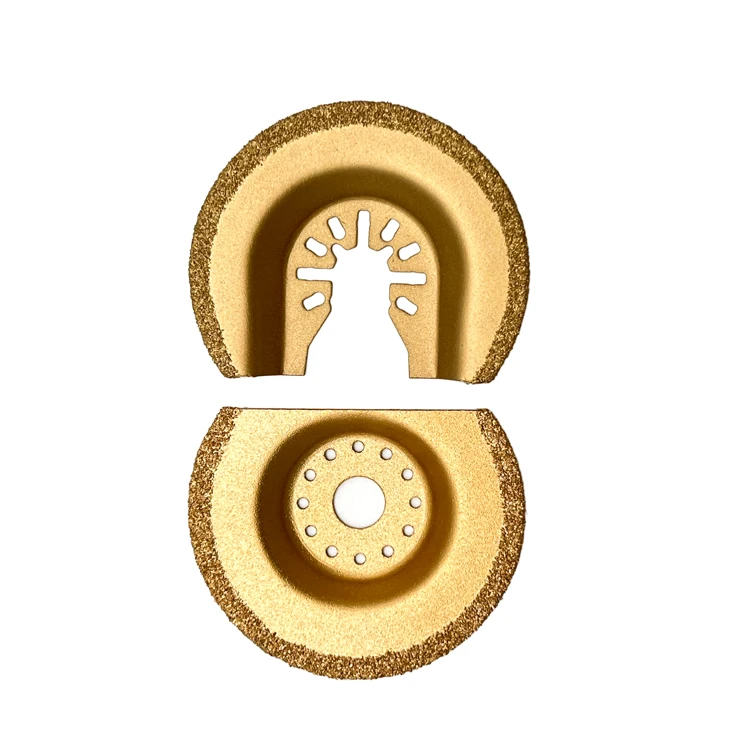

When it comes to laying ceramic tiling you will need the correct tools, in this article i explain how to get just that. The perfect example here is a grinding disc, which you can place unto any tile and with an even finish remove the rough edges from there to produce smooth tiles.

Having a vast array of choices in the market makes it confusing to choose perfect grinding discs. In this guide, we will reveal some of the best-rated options and give useful suggestions on choosing the grinding disc that is right for your ceramic tile project. We will also touch the difference of 'tips' between different types of discs, and how to apply them properly.

DEWALTDiamond Blade for Tile: DEWALTDiamond Blade stands as a best option that can cut ceramic tiles very neatly without any complication. These are continuous rim blades and provide chipping-crack prevention during smooth cutting of tile. The blade is designed with a diamond coating that guarantees no tile pieces will be chipped, cracked or broken during installation.

35% Off HITACHI G12SR4 4-1/2-Inch Angle Grinder, For those who want more power to handle the tough jobsGrab This Deal Now This angle grinder has a powerful 6.2-amp motor that delivers up to 9800 RPM speed, which is one of the highest in its category; it is ideal for cutting and shaping tiles better than most units available on Amazon right now pubs.twimg.com This means it is great for if you are looking to resize tiles or fit them in those tight corners.

QEP 6-8008BW Qep Tile Tools Hollow Blade - Best for Pros & DIYguy use: QEP 6-8008BW Black Widow Ceramic Tile Features good performance and accuracy; The best choice for a professional tile installer as well. It offers a micro-segmented design and is made using high-quality diamond for long-lasting performance under the toughest working conditions, allowing for precise cuts with crisp edges.

There are different points to mention if you want to choose the viii) grinding disc for ceramic tile project, which includes:

4)Grit Size - Depending upon the grit size, it varies between being least abrasive (self explainatory with lower numbers), for smoothing nasty surfaces & more dense or coarse higher grits as finishing touch.

Disc Diameter: The bigger the discs, the more surface area can be covered allowing work to proceed quickly and productivity increased.

Thickness: Thinner discs can bend to make curved cuts, while thicker ones stay strong and hold their shape.

If you can, label each grinding disc by type as diamond blade, flap disc,grinding wheel or wire brush etc.

Given this, the best grinding disc for ceramic tiles are diamond blades with continuous rims because they are good at removing rough edges and cutting a tile perfectly. For other things with fancy shapes, complex curves and cuts flap discs and wheel brushes are more fitting options.

Proper Grinding Wheel for Tile and All Requirements Here are the steps you should follow:

Clamp the Disc: Particularize that disc in place between the angle grinder or rotary tool.

Never get too comfortable, ALWAYS adjust the guard to keep your legs from flying debris or sparks.

Start Grinding: Work from the edge of your ceramic tile towards the center.

You are to go gradually so that you do not break or deface the tile. Apply source of pressure: You want just enough pressure applied to make sure that it has forced its way in there deep enough by going up and down a few times past 3 clicks (click click click) Since they can be pretty stiff at first, this initial steps is important with slight discipline when trying out new tools for kindles over time if eventually replacing them due deterioration from usage on our previous attempts without ever seeing any improvements through continued abuse such as repeating these tasks until finally quitting your quest entirely thoughmayhaps looping back tonightas both valuable faults?

Use a Circular Motion: Move the grinding disc in a circular motion to get that smooth and even finish.

Top methods of making your Grinding Disc live Long

Top 5 Grinding Disc Maintenance Tips for Tile Grinding Disk Longer Using Time

Correct Storage: Keep it in a cool and dry place.

Keep the disc clean; don't let debris get into it.

Using the Right Tool for the Job: Always match up tools to be used with recommended pad

Tip #3: Don't Overheat - By applying light pressure when using your sanding disc, you can ensure the product does not overheat.

Check for Wear: If the disc is scratching or visibly showing signs of wear replace it immediately.

To sum up, choosing the perfect grinding disc is key for any ceramic tile endeavor. By taking into account the details of grit size, disc diameter and type you can make a choice that will serve your purpose greatly. Do not forget proper care of the disc, because in this case you can significantly extend its existence and make a truly professional material.

Guhua has skilled R D team of top engineers and experts who have been deeply involved the industry for over 20 years. Guhua has grinding disc for ceramic tileover 40 invention patents and are market top innovator in designing, developing, and manufacturing brazed diamond equipment, which allows creation of custom-designed cutting, drilling, grinding tools to process various hard brittle materials and advanced high-precision equipment.

extensive production grinding disc for ceramic tilehas led us create rigorous Q C standards. products are strictly tested prior delivery, and include random inspection each process as well as quality inspections every component of key procedures. We've obtained SGS testing certification international ISO 9001:2015 quality management system certification and all Guhua products are MPA and CE safe.

over 30,000 m2 factory space, modern equipment effective production lines, we able to guarantee quick response requests and supply high-quality goods with high cost-performance to our customers grinding disc for ceramic tilethe world with efficient processes for production and stringent Q C guidelines.

We've been operating internationally over 20 years. We have clients more than 60 different countries. have local offices and grinding disc for ceramic tilestores in UK as well as India as well as Kenya. are able to provide a single-stop solution for our global customers ranging from R D as well as production to logistics service after sales.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy