เครื่องตัดคอนกรีตเป็นเครื่องมือชนิดหนึ่งที่สำคัญซึ่งใช้ในงานก่อสร้าง เนื่องจากมีคมพิเศษที่ออกแบบมาเพื่อตัดวัสดุที่แข็งมาก เช่น คอนกรีต ฐ丕 และยางมะตอย วัสดุเหล่านี้สามารถต้านทานได้ค่อนข้างยาก ดังนั้นเราจึงต้องใช้อุปกรณ์ที่เหมาะสม หมายความว่า ใบมีดของเครื่องตัดเหล่านี้อาจเสียหายและจำเป็นต้องเจียรใหม่ เมื่อเกิดเหตุการณ์นี้ เครื่องตัดจะหยุดทำงานอย่างมีประสิทธิภาพ เครื่องตัดอาจไม่สามารถตัดลึกเท่าปกติ หรืออาจเกิดความร้อนสูงและเกิดประกายไฟ ในที่นี้คุณจะได้ทราบถึงปัญหาทั่วไปที่เกี่ยวข้องกับใบมีดตัดเพชร และวิธีการซ่อมแซมที่จะช่วยให้เครื่องตัดของคุณอยู่ในสภาพดีเสมอ

วิธีการแก้ปัญหาทั่วไปเกี่ยวกับใบมีดตัดเพชรที่จะให้ผลลัพธ์เสมอ

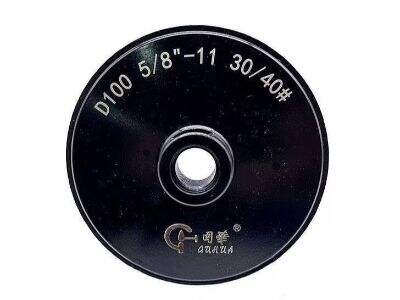

การสึกหรอเป็นหนึ่งในปัญหาที่พบบ่อยที่สุดสำหรับใบมีดตัดเพชรของ GUHUA ซึ่งหมายความว่าขอบมีดจะสึกหรอกับเวลาและทำให้ไม่คม หากใบมีดไม่คม การตัดจะยากขึ้น และคุณต้องระวังไม่ให้มันร้อนเกินไป เมื่อคุณเห็นว่าใบมีดเริ่มสึก จำเป็นต้องเปลี่ยนขอบมีดนั้นก่อนที่มันจะเสียหายมากจนเกินไป ในลักษณะนี้ คุณจะสามารถประหยัดทรัพยากรของคุณได้ จานขัดคอนกรีต ทำงานได้อย่างมีประสิทธิภาพและใช้งานได้จริง

รอยแตกร้าว: ปัญหาถัดไปที่ผู้คนเจอบ่อยครั้ง หากคุณกดลงแรงเกินไป หรือหากใบมีดหล่น มันอาจทำให้ใบมีดแตกได้ ใบมีดที่แตกไม่เพียงแต่ลดประสิทธิภาพ แต่ยังอาจเป็นอันตรายได้ หากคุณเห็นรอยแตกร้าวบนใบมีดของคุณ คุณควรเปลี่ยนมันทันทีก่อนที่จะเกิดอุบัติเหตุที่อาจทำให้คุณบาดเจ็บได้

ปัญหาที่สามที่อาจเกิดขึ้นคือการบิดตัว ซึ่งหมายความว่าใบมีดอาจเสียรูปร่างเล็กน้อย หากใบมีดร้อนเกินไปหรือสั่นขณะตัด ก็อาจทำให้เกิดการบิดตัวได้ ใบมีดที่บิดตัวจะไม่สามารถตัดตรงได้ และอาจทำให้เกิดการสึกหรออย่างมากก่อนเวลาอันควร หากคุณสังเกตเห็นว่าใบมีดของคุณบิดตัว แนะนำให้ใช้ใบมีดใหม่เพื่อการตัดที่สม่ำเสมอ

วิธีการทำให้เครื่องตัดคอนกรีตทำงานได้ดีที่สุดสำหรับคุณ?

การใช้ใบมีดที่เหมาะสม: สิ่งสำคัญมากเมื่อคุณต้องใช้เครื่องตัดคอนกรีตคือต้องแน่ใจว่าคุณมีใบมีดที่ดีและเหมาะสมกับงานที่จะทำ ก่อนอื่นเลย คุณต้องตรวจสอบให้แน่ใจว่าใบมีดคมและพร้อมใช้งานตามจุดประสงค์ก่อนที่จะเริ่มใช้งานในโครงการหรือการประยุกต์ใช้ วิธีที่ดีที่สุดในการใช้ปืนรางก็เหมือนกับสิ่งอื่น ๆ คือการใช้งานตามที่ผู้ผลิตออกแบบมา อีกสิ่งหนึ่ง — เสมอตัดในพื้นที่ที่มีการระบายอากาศที่ดี เพื่อให้แน่ใจว่าเครื่องไม่ร้อนเกินไป

นอกจากนี้ อย่าลืมหล่อลื่นตัวตัดของคุณเป็นประจำ สิ่งนี้หมายความว่าคุณจะต้องทำความสะอาดใบมีดทันทีหลังจากใช้งาน เพื่อไม่ให้มีเศษหรือฝุ่นสะสม นอกจากนี้คุณควรตรวจสอบระดับน้ำมันเครื่องเป็นระยะ หากน้ำมันมีปริมาณต่ำเกินไป จะทำให้เครื่องยนต์ร้อนเกินและเสียหายถาวรได้ การบำรุงรักษาควรทำเพื่อรักษาประสิทธิภาพการทำงานของ ใบมีดตัดคอนกรีต ให้ทำงานได้ดีและยืดอายุการใช้งานของมัน

คำแนะนำในการดูแลและบำรุงรักษา

การบำรุงรักษาเครื่องตัดคอนกรีตเป็นสิ่งสำคัญช่วยให้คุณใช้งานเครื่องได้อย่างมีประสิทธิภาพและยืนยาว การดูแลและบำรุงรักษา

ทำความสะอาดใบมีดทุกครั้งหลังใช้งาน ซึ่งจะช่วยกำจัดฝุ่นและสิ่งสกปรกที่สะสม

ตรวจสอบระดับน้ำมันเครื่องเป็นประจำ หากเครื่องยนต์ขาดน้ำมันจนร้อนเกินไป จะทำให้เกิดความเสียหายในภายหลัง

ตรวจสอบให้แน่ใจว่ามีการไหลเวียนของอากาศที่ราบรื่น เปลี่ยนส่วนผสมที่เป็นมลพิษอย่างสม่ำเสมอ ข้อเท็จจริงเกี่ยวกับเตาเผาแบบ Rocket #2: ฟิลเตอร์อากาศที่อุดตันสามารถทำให้ใบมีดทำงานได้ไม่ดีและร้อนเกินไป

ตรวจสอบหัวเทียนเป็นประจำ หัวเทียนที่สึกหรอหรือสกปรกอาจเป็นหนึ่งในสาเหตุที่ทำให้เครื่องยนต์ของคุณทำงานไม่ถูกต้อง ซึ่งอาจลดประสิทธิภาพการทำงานของใบมีดของคุณ

เก็บใบมีดไว้ในที่เย็นและแห้ง เพื่อหลีกเลี่ยงการเกิดสนิมและการกัดกร่อนของเครื่องมือ

แนวทางปฏิบัติเมื่อใบมีดตัดคอนกรีตมีปัญหา

หากใบมีดตัดคอนกรีตของคุณมีปัญหา คำแนะนำเหล่านี้สามารถช่วยคุณได้:

หากใบมีดเสียหายหรือทู่ ให้เปลี่ยนทันที ใบมีดที่ทู่จะทำให้การตัดยากขึ้นและอาจก่อให้เกิดปัญหาโดยการร้อนขึ้นมากกว่าปกติ

เปลี่ยนทันทีหากใบมีดแตก ใบมีดที่แตกมากเกินไปจะไม่เหมาะสมสำหรับการใช้งานและอาจเป็นอันตรายอย่างมาก

ใบมีดที่เสียหายเกิดการบิดงอ ดังนั้นคุณจะต้องใช้ใบมีดใหม่ ใบมีดที่秃หรือบิดตัว จะไม่ตัดได้ดีและทำให้ ใบมีดเพชรสำหรับคอนกรีต สึกหรอเร็วกว่าปกติ

ใช้ใบมีดที่เหมาะสมกับวัสดุที่คุณจะตัด การเลือกใบมีดผิดอาจทำให้การตัดยากขึ้นและอาจทำให้ใบมีดเสียหายได้

ปฏิบัติตามคำแนะนำของผู้ผลิตในการใช้งานและการดูแลทุกครั้ง เพื่อให้แน่ใจว่าเครื่องตัดของคุณยังคงทำงานได้อย่างมีประสิทธิภาพสูงสุด

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW